Construction

Lanya silanes, siliconates and silicone fluids are used for a variety application in buildings and construction. Lanya provide building protection include anti-graffiti protection, corrosion protection, easy-to-clean effects, stone consolidation, adhesion promoter and depth hydrophobation with alkylalkoxy silanes.

before_after_silicone_treated-150.png

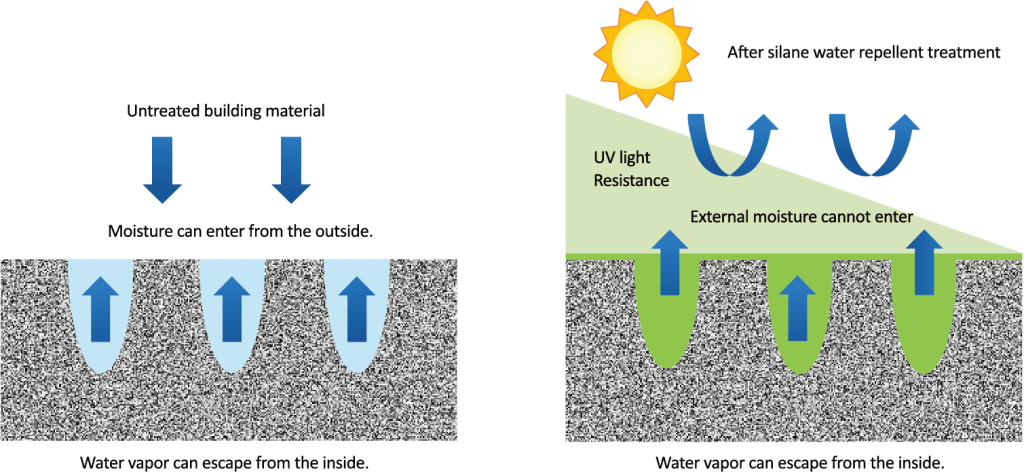

Moisture is the root cause of almost all mechanisms that damage mineral building materials. Their porous nature allows water and dissolved contaminants to penetrate via capillary action from the surface into the interior.

Most siloxanes, especially silanes, are smaller than the pores of substrate, and when applied to the surface of a suitable substrate, penetrate deeply. They react with themselves and any hydroxy (OH) groups within the substrate when moisture is present, forming a silicone resin network. This formation of strong chemical bonds provides the durability characteristic of silicone treatments.

When cured, external liquid water is kept from entering the pores, while water vapor generated from within the structure can still escape. The structure remains breathable. Because they are inside the pores, water repellent treatments are not affected by UV radiation.

Silanes are the smallest silicone molecules, which ensures deep penetration into substrates.

Lanya SILICONES provide different based waterproofing agents:

Creme Based:

It reduce water uptake extremely effectively. It also ensures very good penetration depth and easy application.

Water Based:

They are free of solvents and a perfect choice for absorbent substrates. They are odor-free and require no special ventilation or personal protective equipment beyond eye protection and gloves. They are not flammable. They can be easily diluted on-site, and cleanup of tools and equipment is very easy.

Solvent Based:

Silicone based water repellent treatment do not penetrate as deeply as solvent based treatments on less porous substrates, like dense concrete or stone. This can in some cases make water-based treatments less durable over time, but since durability depends so much on the substrate being treated, environmental conditions and other factors such as the concentration of the treatment, the durability is not completely dependent on the penetration level.

Water-based treatments tend to dry more slowly than solvent based treatments, but unless the temperature is quite low, this is usually not a concern or problem. If possible, a 24 hour dry time is recommended for most water-based treatments before returning the treated area to normal use or before exposure to rain or other water. Ideally, 3-5 days is even better.